Pit Latrine (Dug-Well Latrine): Design, Advantages, Limitations & Improved Models

The limitations of a borehole latrine were:

• Limited capacity: The borehole filled up quickly, requiring frequent relocation.

• Specialized equipment: The construction process relied on an auger, which was not always readily available.

The simple solution was a ‘Dug Well Latrine’ also known as ‘Pit Latrine’

• The volume of a cylinder is directly proportional to the square of its radius

• This is why doubling the diameter (and thus the radius) of a dug well latrine significantly increases its volume, making it more functional and longer-lasting.

• Moreover, a wider pit can be easily dug using simple, widely available tools, making the construction process more accessible and convenient for communities.

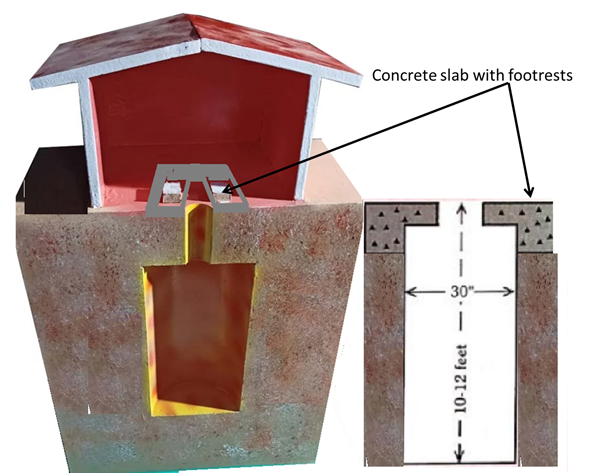

• The method involves digging a circular pit (about 75 cm in diameter and 3-3.5 m deep) to collect waste.

o In sandy soil, a shallower pit (1.5-2 m deep) is used.

• To prevent collapse, pottery rings can be added for support.

• At the top, a concrete squatting plate is installed, and the entire structure is enclosed with a superstructure, providing privacy and protection.

• This system relies on anaerobic digestion, breaking down waste naturally over time.

• First introduced in Singur, West Bengal (1949-1950)

Why Was It a Game-Changer?

• Easy to Build – No special tools like augers needed.

• Longer Lasting – A pit of standard size serves a family of 4-5 for about 5 years before needing replacement.

• More Efficient than Borehole Latrines – The larger pit extends its usability.

o Unlike the narrow borehole latrine, which often filled up quickly and required constant replacement, the dug well latrine offered increased volume, hence a more durable alternative.

Once full, a new pit is dug, making it a low-cost, sustainable sanitation solution that played a crucial role in improving hygiene in rural areas.

The primary drawbacks of pit latrines include:

• Risk of contaminating groundwater sources.

• Limited space for relocating pits, especially in densely populated regions.

• Challenges in construction in areas with rocky terrain or high water tables.

Innovations in Pit (Dug Well) latrine: improving efficiency and overcoming limitations

Ventilated Improved Pit (VIP) Latrine

VIP latrines are an upgraded version of traditional pit latrines, specifically designed to minimize issues related to odors, flies, and mosquitoes.

Key features include a vent pipe, fly screen, and a squatting cover, which enhance hygiene and usability.

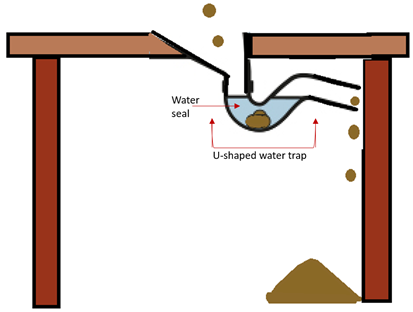

Fitting a water-seal under the pot

A simple pit latrine can be improved by fitting a water-seal beneath the squatting plate.

This modification prevents odors and insect breeding while enhancing hygiene and user comfort.

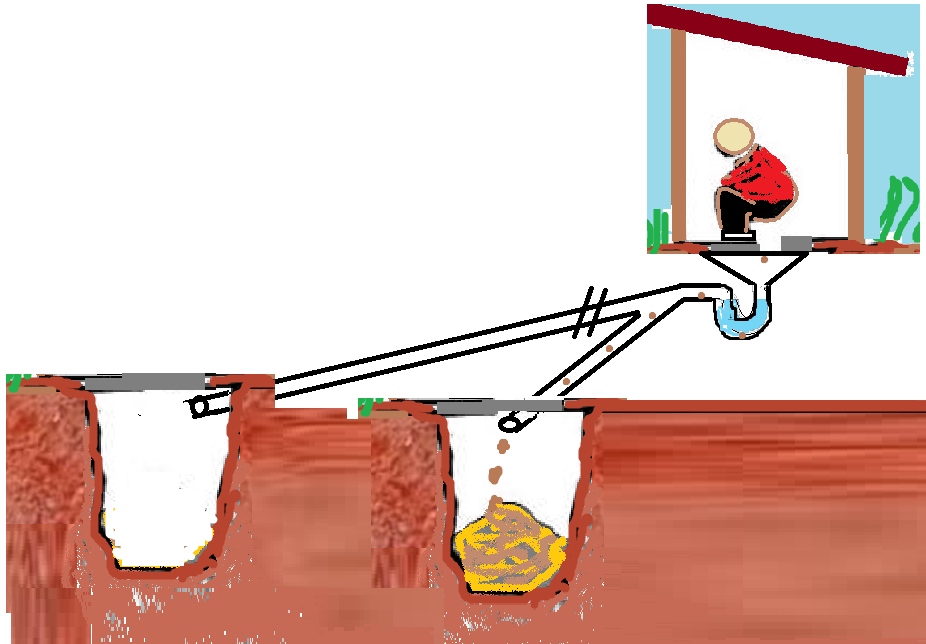

Twin pit:

Pit latrines, also referred to as dug-well latrines, can be constructed as twin-pit systems.

• In this design, when one pit reaches its capacity, the connecting pipe is closed, and the second pit is brought into operation,

• Ensuring continuous functionality and efficient waste management.,

• Allowing for the safe removal of the decomposed waste.

• These latrines work by enabling liquid waste to seep into the surrounding soil while solid waste undergoes anaerobic decomposition, eventually necessitating pit emptying.

References:

• Park's Textbook of Preventive and Social Medicine. 26th ed. Jabalpur: M/S Banarsidas Bhanot; 2021. Environment and Health; p. 799-883.

• Park's Textbook of Preventive and Social Medicine. 27th ed. Jabalpur: M/S Banarsidas Bhanot; 2023. Environment and Health; p. 832-915.

• Bhalwar R. Textbook of Community Medicine. 5th ed. New Delhi: Wolters Kluwer; 2023. Chapter 8, Excreta Disposal; p. 89-101.

• Series 3, Sanitation; WHO website. Available at: https://apps.who.int/iris/bitstream/handle/10665/66334/WHO_EOS_96.4_2.p1... accessed on 28th March 2025

Sanitation Barrier: https://ihatepsm.com/blog/sanitation-barrier-keeping-our-communities-hea...

Excreta Disposal: https://ihatepsm.com/blog/proper-excreta-disposal-necessity-health-and-d...

Video on Sewage Treatment: https://youtu.be/M3iMq4-iFHg

Bore-Hole Latrine: https://ihatepsm.com/blog/bore-hole-latrine#google_vignette

The Dug Well Latrine (Pit Latrine): https://ihatepsm.com/blog/dug-well-latrine-pit-latrine-more-practical-al...

Borehole vs. Dug-Well Latrines: A Comparison: https://ihatepsm.com/blog/borehole-vs-dug-well-latrines-comparison

Water-seal Latrine: https://ihatepsm.com/blog/water-seal-latrine

RCA Latrine: https://ihatepsm.com/blog/rca-latrine

Septic Tank: How it Works: https://ihatepsm.com/blog/septic-tanks-how-do-these-work

Aqua Privy: https://ihatepsm.com/blog/aqua-privy-how-does-it-work